We are Manufacturer, Supplier, Exporter of Conveyorised Powder Coating Plants, Manual Conveyorised Powder Coating Plans, Automatic Powder Coating Plants, Painting Plants and our setup is situated in Pune, Maharashtra, India.

Manual / Automatic Conveyorised Powder Coating Plants / Painting Plants

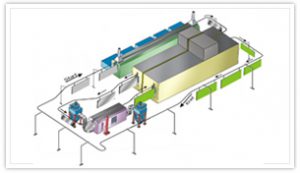

Typical Conveyorised Powder Coating Plant

Conveyorised Powder Coating Plant with 27mtr long oven installed in UAE.

The Conveyorised Plants are recommended production volume is high. A simple Overhead Chain Conveyor passes through Booth and Oven and coating is done with manual Spray Guns. Conveyor speed is worked out based on production rate required and oven can be straight tunnel type or with loops inside it. For large size components as openings are large camel back oven is recommended wherein heat losses are minimized. normally up-to 1mt speed this plant is workable.

• Automatic Conveyorised Powder or Painting Plants

This is similar to abode but coating / painting is done with the automatic Guns / Applicators. Here Conveyor speed is

high and it is impossible to coat the entire component manually. The guns are mounted on reciprocators and it is

synchronized with conveyor speed. Auto applicators are beneficial due to automation and saving in powder/ paint. Further

coating quality is superb as uniform coating is possible. In all cases oven can be electrical / gas fired or diesel

fired depending upon availability of fuel.